CNC-12-45No CAM wire bending spring forming machine

1. Overview:

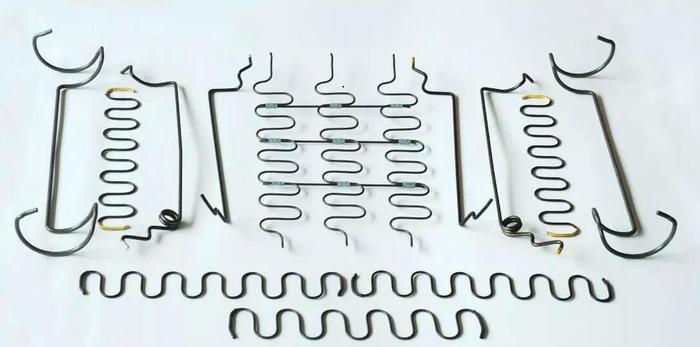

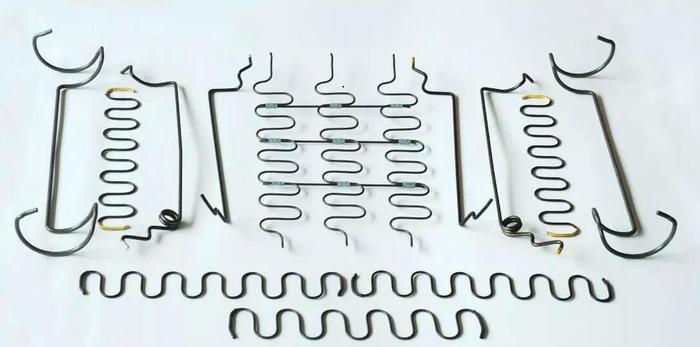

Unique cam-free and non-rocker arm design, controlled by multiple groups of servomotors independently, can produce a variety of special-shaped springs, compression springs, double torsion springs, battery springs, flat springs (spring springs) and a variety of wire molding, bending wire, etc. Precise, accurate, fast, stable and reliable.

Features and functions of the machine:

1, no CAM, no rocker arm design (the speed of the adjusting machine is more than 50% faster than the traditional CAM machine, the production speed is fast, accurate positioning, stable operation).

2, Full rolling guide rail can keep the accuracy for a long time.

3, no collision and heat, composite tool to complete all procedures, low tool loss.

4, Intelligent module, automatic detection and alarm.

5, Windows window operation, English and Chinese display, easy to learn and use.

6, domestic original use of camera photo detection, and can automatically correct the function, better improve the precision of the machine!

2.Some parameters

Model | CNC-12-45 |

Wire diameter | 1.2-4.5mm |

Maximum wirefeed instruction value | 10000.00mm |

Minimum line feed instruction value | 0.01mm |

Maximum wire feed speed | 100m/min |

Maximum feed length | Infinite |

Number of shaft | 12shaft |

Servo motor output total power | 24000W |

Input voltage | 380V |

Computer specifications | Pentium industrial computer |

Process data storage | More than 2000 |

Air pressure system | Air pressure | 5-6KG/cm |

Probe | Three |

Machine size | Thickness | 2200mm |

Width | 1760mm |

Highly | 2100mm |

Machine weight | 3800KG

|