1.Product details

2.Configuration details

Accessories name brand origin

Servo motor, encoder SANYO

Straight slide track Taiwan silver

Switching power supply Taiwan Ming wei

Fluorescent screen Taiwan au - ta

Inverter Taiwan delta

CNC system silver big topcom

Bearing NSK Japan

Speed reducer: Germany twistat/Taiwan pinghong

The frame is made of A3 steel

Logitech keyboard

Computer motherboard topcom

Ball screw Taiwan silver

3.Yinfeng automation --Innovation of science and technologyAdvantages of wire forming and bending equipment

1. computer startup, shutdown speed is fast, simple and convenient to operate, support multi-language operation, the computer interface can adjust the speed and change the program at the same time of production;

2. the configuration of the use of imported high-precision high-speed servo motor, imported reducer, stable and durable production speed is more than 30% higher than the domestic counterparts of the same kind of products;

3. The production process can achieve no change in the Angle when the Angle is folded at different speeds, and the production stability is better;

4. bearings, gear and other important parts of the imported parts, 9125 hours of warranty, durable and reliable equipment;

5. high precision, can be made within the range of 2.0-14 mm wire diameter wire molding products, the error is reduced to 0.1mm;

6. Perfect after-sales service system: respond within 12 hours of working days nationwide, arrive for maintenance within 48 hours, and provide technical training support free of charge! Equipment lifetime maintenance.

4.Technical parameters

Model No. 2 dcnc-408

No. Of Axis 4

Input processing line diameter OD of hard Wire material hard material Φ 3.0 ~ 6.0 mm phi,Soft material soft material Φ ~ phi is 8.0 3.0 mm

No. Of Feeding Round 3 groups

The Power of Wire Feeding Motor is 3.5kw

Angle shaft servo Motor Power of Angle Control Motor 2.0kw

Power of Wire Cuter Motor 1.0KW

Power of Moving Motor 1.0kw

5.Feature description -- advantages of yinfeng automation innovative technology wire forming and bending equipment

1、電源電流及電壓1秒種以上波動應保證在±5%以內,設備可以正常運行。

2、自動送料架與主機間隔距離2000mm以上。

3、設備配備有USB接口,可實現數據讀取。

4、電腦操作系統具有檢查裝置,不正常時可以自動停機, 在人機界面有顯示,且達到規定產量后設備可自動停機。

5、設備使用后齒輪箱及導軌滑塊要定期加潤滑油脂,周期60個工作日。

6.Maintain details -- Yinfeng automation innovation technology wire molding bending equipment advantages

1. Correct installation and placement

After the machine is placed in the workshop, the need for sufficient ground grounding, manufacturers in the process of transportation, there is a board at the bottom, the need to take the board off, pad rubber pad, the purpose of this is to prevent wire molding machine production process, not due to the machine running vibration.

2. Add oil and butter regularly

Refueling position is mainly curly, wire box, and transmission gear and other places, long-term maintenance of the wire forming machine part of the running in place of oil lubrication, generally a week to check the butter.

3. Keep the machine clean

Every day before work, the staff need to clean the surface of the wire forming machine. If it is not cleaned for a long time and oil is accumulated, there will be the possibility of changing the circuit parameters, and long-term erosion of dust, so that the machine surface aging, affecting the appearance.

4. Normal operation and use

Special care should be taken not to produce products beyond the line diameter range, so as not to reduce the accuracy of the equipment. The machine should be placed in a ventilated and dry place to prevent moisture from rusting or damaging the circuit. Can achieve timely and careful maintenance of the machine, can maintain the precision and stability of the wire molding machine, extend the service life, but also can reduce the repair rate of the machine.

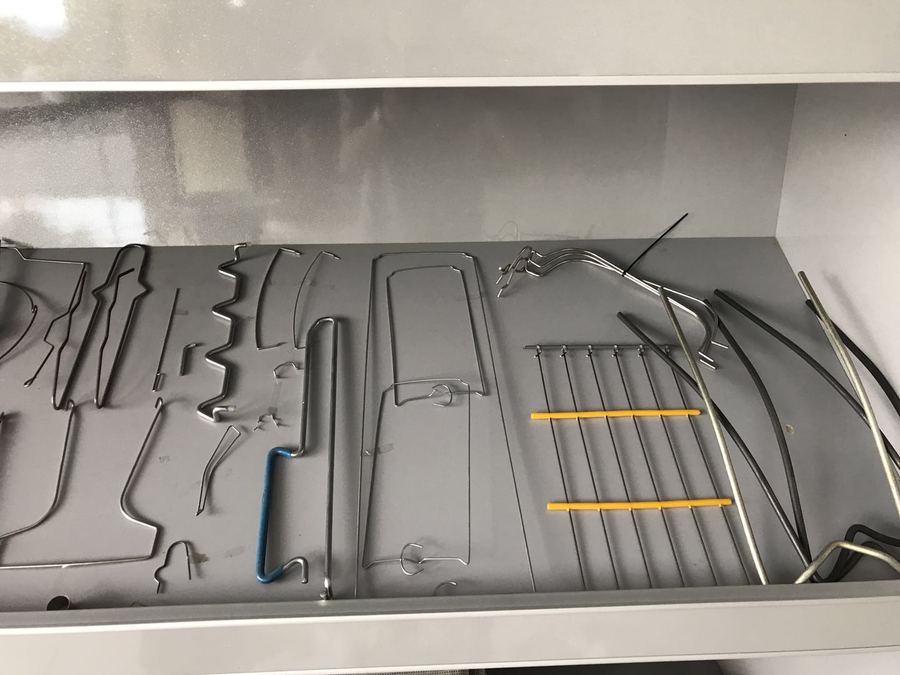

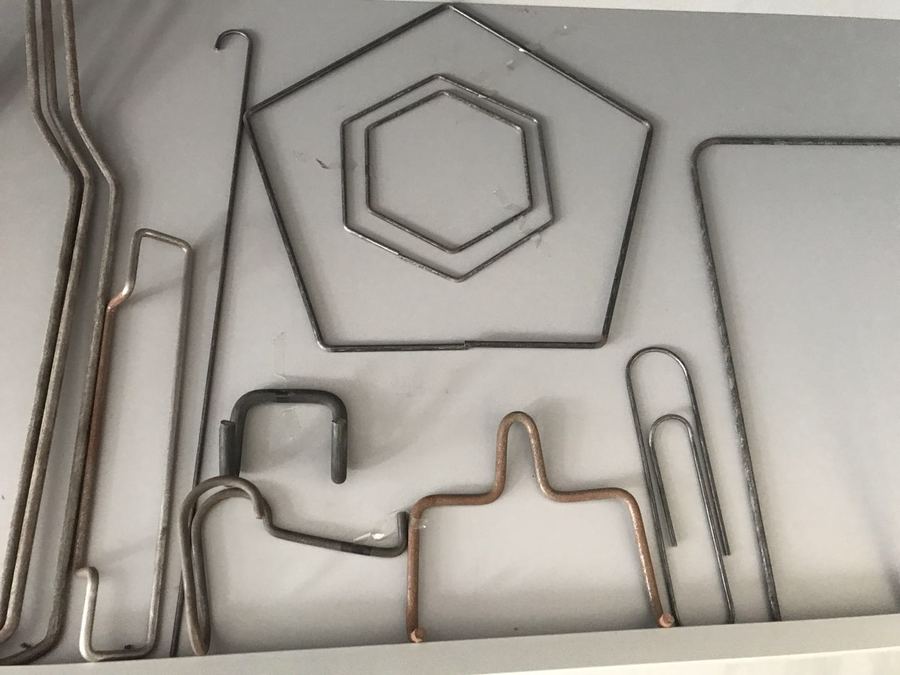

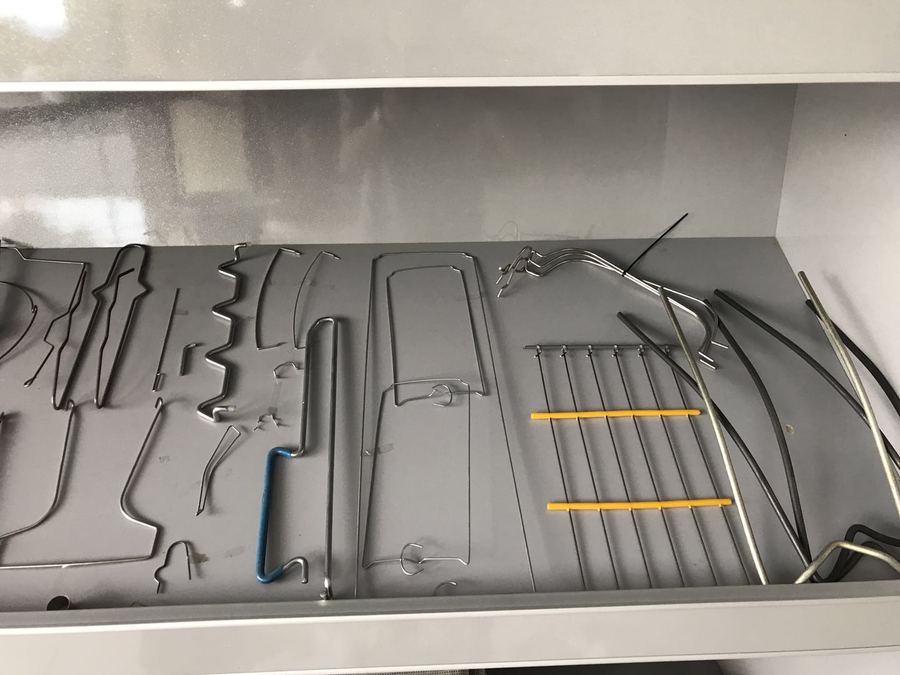

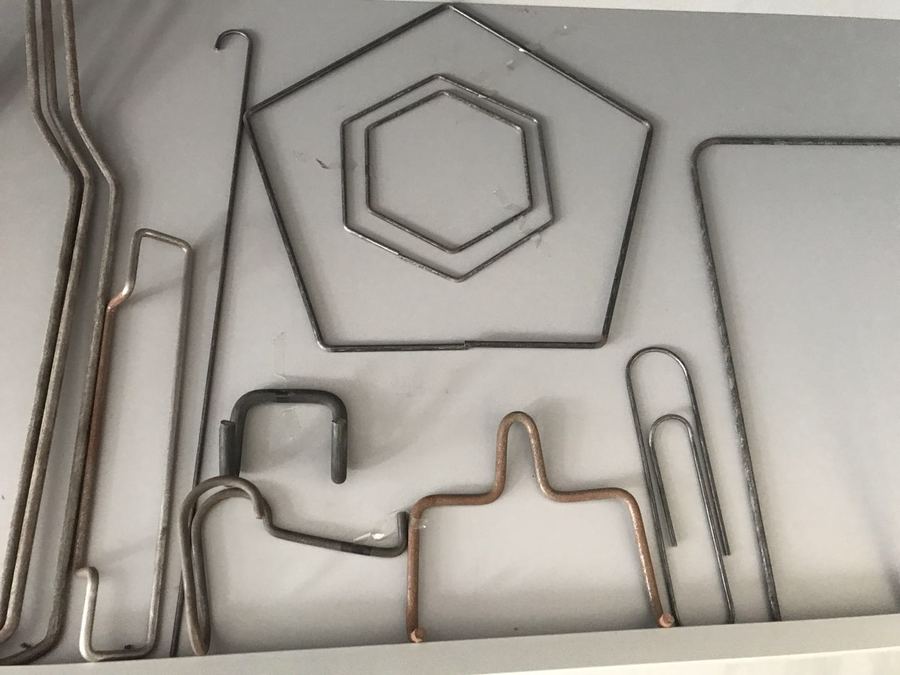

7.Part of the sample sample -- yinfeng automation innovation technology wire molding bending equipment advantage

Tips: pictures on the website are limited. There are more product drawings for this model. For details, please call WeChat: 15005786518

If you have a design, but do not know which device to choose, you can online QQ or WeChat phone 15005786518 consultation, we will give you the first time to reply!