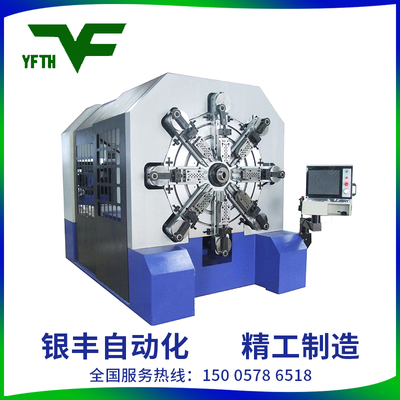

CNC-12-80Cam-free wire forming spring machine

Product features:

1. Twelve groups of servo motors independently control eight stations, including core rotation, wire feeding, warp rotation and wire rotation. Quick adjusting machine (more than 50% faster than CAM machine, more than 10% faster than similar products)

2. The drive mode of imported servo motor and precision ball screw ensures high precision, long service life and high stability.

3. The cutter seat adopts parallel heavy load double guide rail sliding block to ensure high rigidity.

4. Simple operation, friendly interface, computer automatic detection of the health status of the whole machine and alarm.

5. The manufacturing process of high-precision wire box gear can keep the wire feeding accuracy for a long time.

6. Broad application core, suitable for the production of a variety of special-shaped spring, wire forming, tension spring, compression spring, torsion spring, flat spring, volute coil spring, etc.

Specification and parameter scale:

Model | CNC-12-80 |

Wire diameter | 2.0-8.0mm |

Maximum wirefeed instruction value | 10000.00mm |

Minimum line feed instruction value | 0.01mm |

Maximum wire feed speed | 80m/min |

Maximum feed length | Infinite |

Number of shaft | 12shaft |

Servo motor rated output total power | 50KW |

Input voltage | 380V |

Computer specifications | Pentium industrial computer |

Process data storage | More than 2000 |

Air pressure system | Air pressure | 5-6KG/cm |

Probe | Three |

Machine size | Length | 3150mm |

Width | 2130mm |

Highly | 2400mm |

Machine weight | 7000KG |