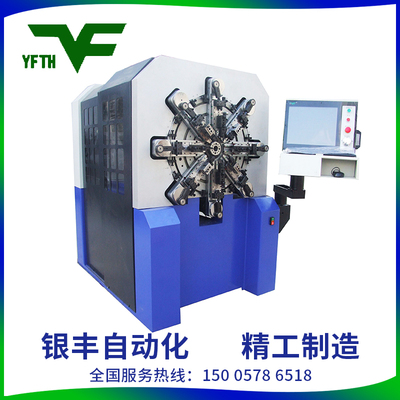

Product features:

1. Twelve groups of servo motors independently control eight stations, including core rotation, wire feeding, warp rotation and wire rotation. Quick adjusting machine (more than 50% faster than CAM machine, more than 10% faster than similar products)

2. The direct connection transmission mode of servo motor and precision planetary reducer ensures high precision, long life, high stability, and overcomes the disadvantage of low stability of other transmission modes.

3. The cutter seat adopts parallel and double guide rail sliders, and has high-speed transverse moving cutter seat, which makes the tuner more flexible.

4. Unique eccentric shaft with double end support, more stable and more rigid spring with large wire diameter.

5. High precision transmission box gear manufacturing process, the whole gear transmission line structure, faster and more stable speed.

6. 360 degree rotation of the arm station, strong line forming ability.

7. Wide application core, suitable for the production of various special-shaped springs, paper clips, tension springs, compression springs, torsion springs, flat springs, volute springs, etc

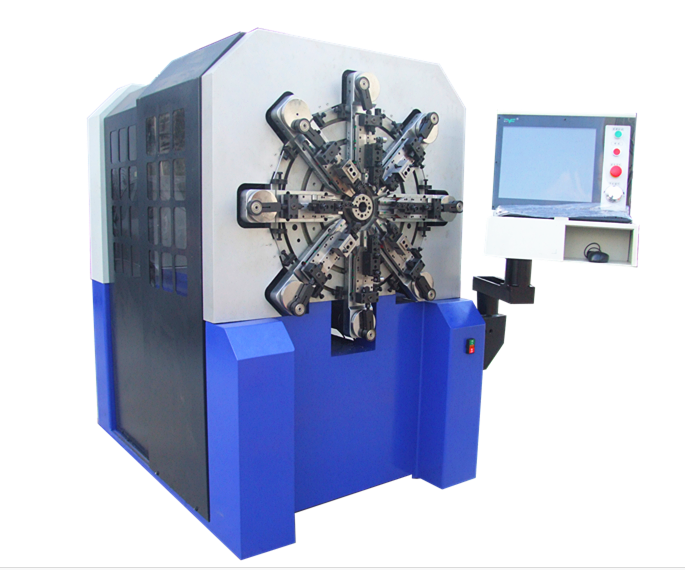

Specification and parameter list

Model | CNC-12-28 |

Wire diameter | 0.4-2.8 |

Maximum wirefeed instruction value | 10000.00mm |

Minimum line feed instruction value | 0.01mm |

Maximum wire feed speed | 80m/min |

Maximum feed length | Infinite |

Number of shaft | 12shaft |

Servo motor rated output total power | 50KW |

Input voltage | 380V |

Computer specifications | Pentium industrial computer |

Process data storage | More than 2000 |

Air pressure system | Air pressure | 5-6KG/cm |

Probe | Three |

Machine size | Length | 1550mm |

Width | 1250mm |

Highly | 1760mm |

Machine weight | 1500KG |